Packaged water, popularly called “pure water” in Nigeria, is a popular business. There are NAFDAC requirements for pure water production plant to protect the population from dirty and contaminated water.

In this document, we will explain all the necessary steps you are bound to take if you want to start a sachet or bottled water plant in Nigeria, and also the documents that will be needed.

You can access the full document of NAFDAC requirements for pure water production here.

NAFDAC Requirements for Pure Water Production

Register a Trade name with the CAC

- The first major step is to register the company with the Corporate Affairs Commission (CAC) in order to secure a business name. It can be registered as an Enterprise (takes two weeks or fewer for CAC to process this application), or as an Incorporation (Ltd). Incorporation takes at least 60 days to process and requires the service of a lawyer, accountant or company secretary.

Registration of Trademark

After incorporation, the next stage in getting a NAFDAC number for sachet water/bottled water is the trademark registration. This is done at the Federal Ministry of Industry, Trade and Investment. The product should be associated with your trade name, but it is not compulsory.

Choose the specific Class Specification of Goods/Services in the trademark registration (water products come under Class 32). There are different categories of products and services. Make sure you select the right category.

If your trademark is uncontested, you will receive a notification within two months, and subsequently, your trademark certificate.

How to Set up the Sachet Water/Bottled Water Factory

This is the next step after trademark registration. NAFDAC requirements for pure water production are divided into two major steps:

- Pre-production/advisory inspection

- Construction/equipping

Pre-production/advisory inspection

After getting your trademark and CAC registration, the next best step is to invite NAFDAC to the sachet water/bottled water site location for the Pre-production/Advisory Inspection. This is necessary to allow NAFDAC to inspect your factory and make sure it meets their requirement.

NAFDAC will inspect and advise you on the appropriate source of water, raw material store, distance of borehole to septic tank, among other details.

Construction/equipping:

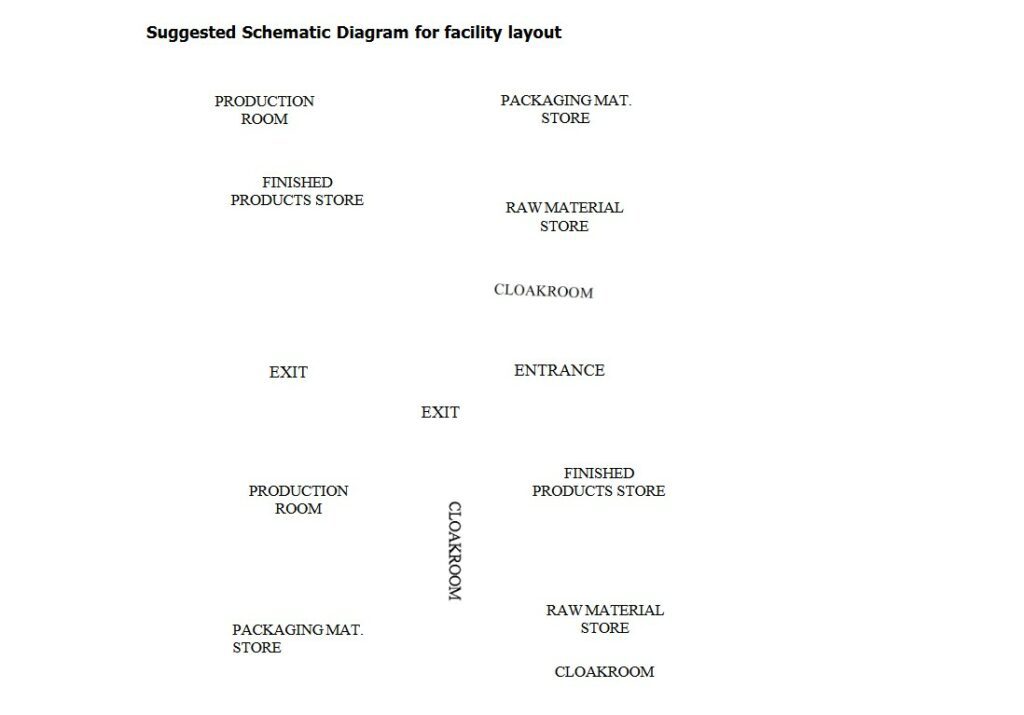

After your site is approved by NAFDAC inspectors, you can start the construction process. The sections should follow the following flow: Cloakroom, packaging material store, raw material store, production section, finished products store.

The room windows should have insect-proof nets. If you wish to produce both sachet water and bottled water, there must be a section for each. The equipments and sections should be labelled correctly.

An accessible convenience room that is not close to the production section is necessary.

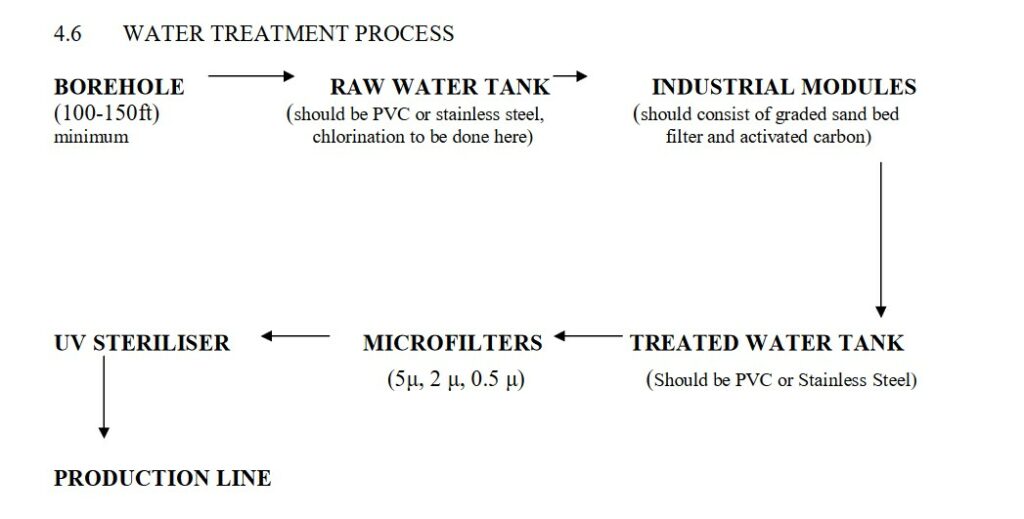

In areas without municipal water (public water system with appropriate water treatment, storage and distribution pipe), a borehole with the depth of 150ft or deeper is needed. You also have to run the plumbing work, water laboratory analyses.

Using the NAFDAC guideline, install the water treatment plants and water producing equipment.

Registration with NAFDAC

After satisfying all the above steps, the next stage is getting the NAFDAC registration number. There are two steps:

- Before Application for Production Inspection

- Production Inspection by NAFDAC Inspectors

Before Application for Production Inspection

The next step after building the packaged water factory is for NAFDAC to come and certify your sachet water or bottled water factory, and bless you with the NAFDAC number. However, there are things you must have in place before the production inspection they are:

- Production staff, with a Production Manager who has at least an OND certificate in a science course from a recognised institution in Nigeria.

- Both production and non-production staff must have a Food Handlers Certificate issued by a hospital after a thorough medical checkup. This will ensure each of them is fit and healthy enough to handle products meant for public consumption.

- A retainership agreement between the sachet water factory and a medical facility to handle their health issues.

- Proof of recent fumigation of the factory by a certified fumigation company. There should be an agreement between the factory and the fumigation company on subsequent fumigation needs.

- A detailed laboratory analyses report of your raw water before treatment (borehole, municipal water) or treated water from your water treatment plant. A qualified analyst from the Institute of Public Analyst of Nigeria (IPAN) laboratory will be needed.

- If you do not have an in-house Quality Assurance Department, an agreement must be made between the factory and IPAN laboratory for analyses of subsequent batches of produced sachet and bottled water.

- There should be Standard Operating Procedures (SOP) for the production, Quality Control, equipment maintenance, sanitation in and around the premises, product distribution and recall, hygiene etc. written and signed by the Production Manager.

- The company organogram showing the key personnel, names, designation, qualification.

- Appointment letters with the letters of acceptance for key employees.

- The credentials of key personnel, especially the Production Manager.

- Full flowcharts of your sachet/bottled water production process showing water source, the production process, and treatment.

- A full list of equipment, the name of suppliers, and their contact information.

- The geological survey of a borehole with information about the terrain, depth of drill, etc.

- The copies of the labels with all the details of the sachet or bottled water as specified in the trademark. Information on the label includes product name, company logo, physical address and contact info of the factory, batch number, volume capacity, date of manufacture and expiry of products.

The above listed documents will be submitted alongside the CAC certificate, proof of Trademark registration, proof of statutory fee payments to NAFDAC (fees for factory production inspection and laboratory analyses of produced water samples after inspection) and Application for Production Inspection. The submission is made to the NAFDAC office in the state of the factory location.

Production Inspection by NAFDAC Inspectors

After the review and approval of your application by NAFDAC, a date is scheduled for the Production Inspection.

On the date for production inspection, you are expected to provide the original forms of your documents, and four copies of such documents. The production manager will be in charge, representing the company that day. He/she will take the NAFDAC inspectors around and handle the questions. All personnel should acquaint themselves with the Standard Operating Procedure. The factory should maintain a high level of sanitation.

Their inspection will involve reviewing your documents to ascertain whether they are original. Other inspections include the interior and exterior surroundings, labelled room areas for proper furnishing, fittings and equipping, borehole and the distance to septic tank, raw water source, water tanks, treatment plants, production equipment, production processes and SOPs.

If the NAFDAC inspectors are satisfied with the factory and production processes, a sample of your sachet or bottled water will be taken to the NAFDAC laboratory for analyses. The tests are microbiological tests and chemical tests. If the packaged water passes the laboratory tests, a notification is issued by NAFDAC informing you to expect the number in two months.

However, if the NAFDAC inspection notices any irregularities or faults in your factory settings or production processes, they will issue a Compliance Directive (CD). This directive will show the full information about their observations and items that do not meet NAFDAC requirements, and what actions should be taken to solve them.

After resolving the issues listed in the CD, you have to write to NAFDAC to notify them that you have undertaken the necessary actions. Then also write an application for Re-inspection (with the payment of Production Re-inspection fees).

During re-inspection, raw and treated water from the factory is taken to NAFDAC for laboratory analyses. If the packaged treated water fails the laboratory test again, you will be required to troubleshoot the whole water treatment process. Another laboratory test by your IPAN laboratory partner will also help in identifying the main fault and fix it.

You must meet the NAFDAC requirement for packaged water before the number is issued to you. It is also important to note that even after issuing the NAFDAC number, you will have to maintain the standards because NAFDAC inspectors do pay unannounced visits to factories. Disciplinary actions such as fines, bans are imposed on factories that disobey rules, regulations and standards set by NAFDAC.

Statutory Fees for NAFDAC Inspection of Sachet or Bottled Water Factory (VAT of 5% applicable) are:

- Sachet Water:

- Production Inspection = N10,000

- Renewal Inspection = N5,000

- GMP Reassessment = N10,000

- Follow-up inspection = N10,000

- Advisory Inspection = N10,000

- Laboratory Analysis = N10,000

- PET bottles (Jars, cans):

- Production Inspection = N10,000

- Renewal Inspection = N5,000

- GMP Reassessment = N10,000

- Follow-up inspection = N10,000

- Advisory Inspection = N10,000

- Laboratory Analysis = N20,000

I hope you now have a clearer idea about NAFDAC’s requirements for pure water production. Leave a comment below.

This is a very helpful, I will be going into it by next year fully…

Thank you, and success in your future endeavour

Thanks for this thoughtful post. Please can you help me with NAFDAC contact in Edo state.

It a burning desire to setup a factory soon and your corporation will be highly required.

You are welcome. We will help in any way we can sir

Thanks so much for the detailed information. God bless you

We are pleased to have served you with the needed information

I’m most grateful to have all this information as I plan to set up a factory by next month. Please if I can get a number to call will go a long way. Thank u

Thank you. Kindly visit any NAFDAC office close to you and make all the enquiries

am so much pleased with the detailed explanation, i hope to set up one plant as soon as possible, i believe i will have the full support and approval of the NAFDAC office when its time.

May God bless your efforts

This is well pleased explanation. Hope to start fully soon, but still don’t have idea of a start up capital after construction of the site.

You can apply for a loan, or alternatively wait patiently for business grants such as TEF Grant

Thanks for sharing this vital information.

Please what’s the total cost of registration for sarchet water.

I mean total cost

Am very interested but not in a very big way

wonderful!

thank you so much , this is just what i needed to hear.

Nice writeup, how do I apply for renewal on line

Thanks so much.please I need NAFDAC contact number or address in Akwa Ibom State.

Very vital information may God almighty bless you with this information you share

Amen. Thanks for the compliment.

the timeframe for the release of number is too long. can there be ny adjustment or fast track?

Please what is the specification/maximum limit for Microbiology Total plate Count of packaged drinking water

visit nafac office closer to you for more clarification, some information here are old . nafdac official payment for registration (sachet water) is very close to 80k